Development of hot melt adhesive film

Release time:

2021-07-21 15:50

Source:

Www.goaden.com

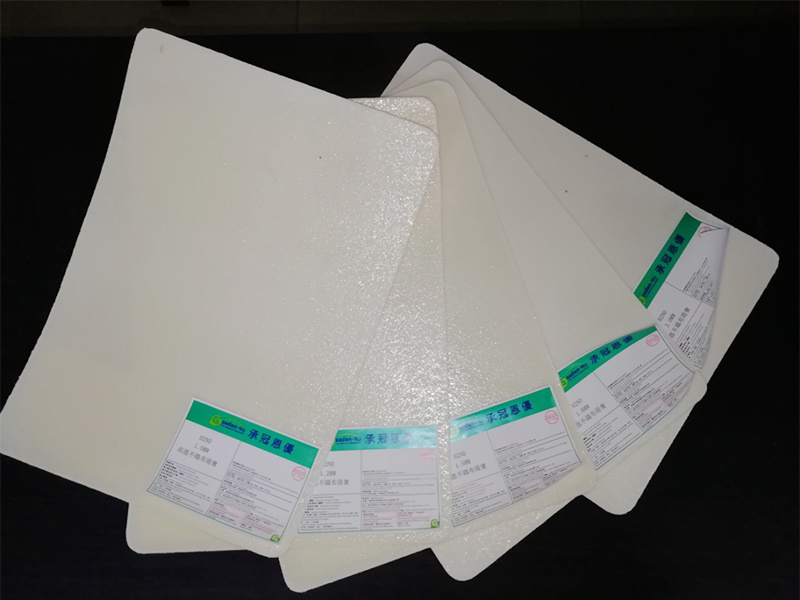

hot melt adhesive filmUnder normal temperature, it is a film made of a material that can melt and bond adherends to a certain thickness without any stickiness. However, as long as the stickiness is immediately reflected after high temperature, the fabric to be compounded can be successfully compounded quickly without any trace of glue.

At present, the main hot melt adhesive films on the market are: PA, PES, EVA, EAA, TPU, etc. The characteristics of each hot melt adhesive film are also very different. Therefore, when selecting the hot melt adhesive film for compounding, one must understand the needs of the hot melt adhesive film and the composite products, so as to correctly select the appropriate hot melt adhesive film!

At present, there is also about hot melt adhesive mesh film. In fact, it is an environmentally friendly and low-cost adhesive newly developed on the basis of hot melt adhesive film, and it is a non-woven hot melt adhesive product. It can be operated continuously or intermittently as easily as hot melt adhesive film, and it also plays an important role in various fabrics, paper, metal, leather, etc. The main types are PA, PES, EVA and TPU. Hot melt adhesive mesh film is more breathable and environmentally friendly than hot melt adhesive film. Therefore, for the working environment, the requirements of hot melt adhesive mesh film will be relatively high, and it needs to be produced in a constant temperature working environment.

Whether it is hot melt adhesive film or hot melt adhesive mesh film, compared with traditional glue, it is more environmentally friendly and not easy to fall off. It is a good choice for compounding now! At present, the traditional adhesive industry is also changing to the hot melt adhesive industry. In the future, the hot melt adhesive application industry will become more and more extensive!

Hot melt adhesive film is a kind of plastic adhesive, which belongs to environmental protection chemical products. Its physical state can be changed with temperature change within a certain temperature range. The chemical characteristics of hot melt adhesive film are unchanged, and it is non-toxic and tasteless. Hot melt adhesive film is used in the bonding between two different substances, not only the bonding performance is superior, but also the washing resistance is relatively strong, and become a lot of heat-resistant textile seamless bonding heat transfer material.

At present, the hot melt adhesive films in the market include PES, PA, EAA, EVA, TPU, etc. This hot melt adhesive film is widely used in the bonding of embroidery labels, armbands and trademarks. It is suitable for clothing, shoes and hats, luggage, medical treatment, military coats, sportswear, toy products and other fields. It is an ideal environment-friendly adhesive material and has low melting point, high elasticity, dry resistance, washing, colorless transparency, wear resistance, cold resistance, antibacterial resistance, acid resistance, mildew resistance, mildew resistance and mildew resistance and other properties.

Hot melt adhesive film has a good reputation in the embroidery industry because of its firm adhesion, convenient operation, low cost and ability to replace traditional sewing needles. It is also called hot melt adhesive and back adhesive. Over the years, with the continuous progress of hot melt adhesive film technology, it has gradually replaced low-quality and rough seam LOGO. This hot melt adhesive has become the most certain adhesive film in the electric embroidery industry.

Related News

Overview of TPU hot melt adhesive film

TPU hot melt adhesive film is also called TPU hot melt double-sided adhesive, is one of the types of hot melt adhesive film, belongs to the environment-friendly hot melt adhesive, it has no viscosity at room temperature, but under high temperature conditions, double-sided adhesive, can be two different materials bonded together.

The purpose and scope of use of low temperature harbor treasure

Today, I 'd like to introduce to you the use and scope of application of the low-temperature harbor treasure.

Discussion on Low Temperature Port Treasure

Today, let Cheng Guan introduce what is a low-temperature port treasure. The so-called low-temperature port treasure is used under the heel of the shoe to make the heel play a fixed role. The material used is a bit like cardboard, which is relatively hard, but glue is used when fixing the low-temperature port treasure and the shoe. The low temperature port treasure according to the material is generally divided into the following three kinds 1, leather pulp low temperature port treasure Soaking water softening method, this kind of low-temperature port treasure is made of cowhide midsole leather as the material of low-temperature port treasure, which is also the softening method used to make leather shoes by hand. At present, Italian leather shoes are trapped in traditional ideas, and this kind of low-temperature port treasure is often used, which is not in line with economic benefits. 2, chemical film low temperature port treasure Soaking solvent (toluene) softening method; this kind of low-temperature Hong Kong Bao immersion solvent can be softened, which is one of the revolutionary shoe materials in the shoe industry in recent years. Its characteristics for soaking solvent can be very soft, the most conducive to footwear molding, without adding or strengthening any treatment, drying and cooling can achieve a stiff effect, for the shoe industry to use more ways. Advantages: cheap, easy molding. Disadvantages: thick, long forming time. The worst elasticity. 3, hot melt adhesive low temperature port treasure Heating softening method: heating (about 100-120 degrees) is used to soften the "hot melt adhesive" pre-pressed to the lining position in front of the shoe, so as to facilitate gang forming. its advantages are fast, thinner and more elastic than ordinary low-temperature port treasures. Disadvantages: molding difficulty is high, heat control is not easy. Dongguan Chengguan Enyou Material Technology Co., Ltd. is a Taiwan-funded professional hot melt adhesive manufacturer. The company has achieved advanced and excellent development since it was put into production in 1980. The company has 5,000 SQM in its production workshop and seven advanced production lines with a daily output of 100,000 SQM. The main products are: hot melt adhesive molding network, Dongguan hot melt film, low temperature Hong Kong Bao, Hong Kong Bao, hot melt film, hot melt adhesive film, etc. Very professional technical support.

The effect of different hot melt film

Hot melt film is a product developed in recent years, but it has developed rapidly and has been recognized and mastered by many people. This is to melt the rubber by electric heating, and the rubber is extruded from the muzzle to bond the adherend. The operation is convenient, the curing speed is fast, and the bonding strength is reached after a few seconds. Many types of hot melt film are specifically used in the industrial field, and their strength and durability far exceed those used in regular hardware/handicraft products. For example, the seam tape used in carpet production is stuck with a special hot melt adhesive, which makes the quality of carpet seams durable.

The type and composition of hot melt adhesive, commonly used hot melt film mainly has PA/PES/TPU/EVA/LDPE/HDPE and so on.

Where are hot melt films used?

Hot melt film are used in what place: 1. fabric with hot melt film: mainly used in shape, shoes and hats production. The garment using the adhesive not only has a good appearance quality, but also has the characteristics of natural and smooth after washing, and can be worn without ironing. The shoes and hats using the glue are light and breathable, with good shape retention, especially suitable for the shoe industry, and also have the advantages of comfortable wearing and reducing shoe odor.